The Tesla Cybertruck revolutionized the automotive industry with its groundbreaking 48V electrical system and steering-by-wire system. Of course, if the wiring harness does not have a new way of wiring, communication methods do not have a new change, this revolutionary progress is impossible to achieve.

Tesla Motors has recently applied for a patent and is eyeing wiring harnesses.

Cybertruck may look a little underwhelming, and it doesn't feel as good as Musk previously said it would.

However, Cybertruck's advanced technology did not disappoint.

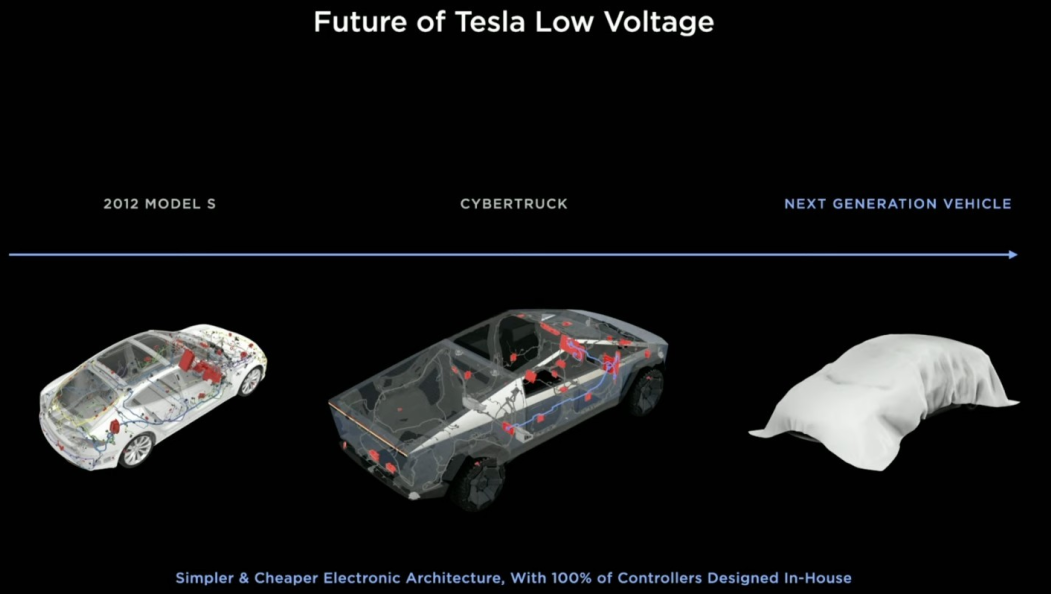

One of them is the 48V low-voltage electrical system(low-voltage electrical wire harness) used in production vehicles for the first time. By dramatically improving and simplifying the electrical architecture, Tesla will be able to build the next generation of electric vehicles at a better cost.

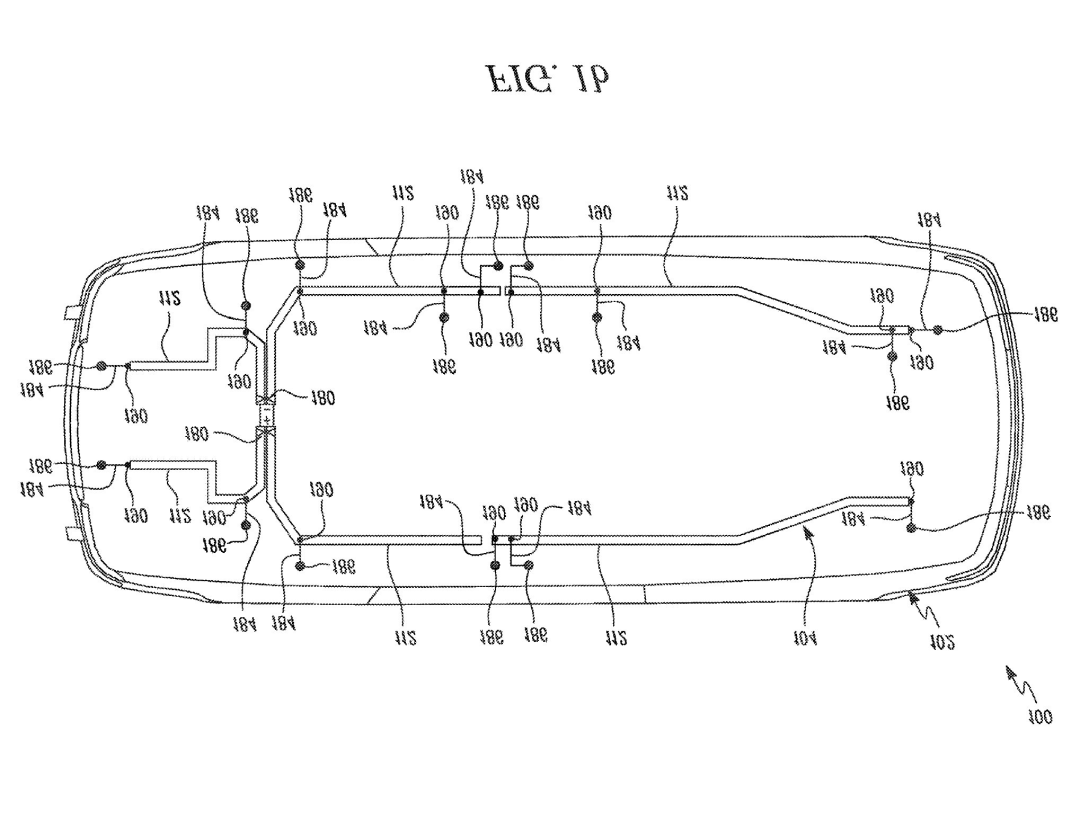

Tesla has announced that Cybertruck's cabling architecture will be significantly simplified compared to previous Tesla electric vehicles. Tesla achieves this by using multiple local controllers connected to a high-speed communication bus instead of connecting each electrical component to a central controller.

To understand this situation, it is necessary to talk about traditional vehicles.

Typically, every sensor and electrical component on a vehicle must be connected to a central controller and low-voltage system to obtain power. Sometimes, this means complex parts require a lot of wire. Let's take doors for example. It may contain sensors that signal to the car's computer that the car is on, off, or tilted. The same is true for Windows, which have buttons that trigger opening and closing. These switches are connected to the vehicle's controller, which in turn is connected to the window actuator to lower or raise the glass.

That's when we add speakers, airbags, cameras... You'll understand why the harness is so messy. Wires in modern vehicles extend for many kilometers, adding complexity, cost, and weight. To make matters worse, building and installing them is mostly done by hand. These are expensive and time-consuming processes that Tesla wants to eliminate.

That's why it came up with the idea of a distributed controller. Vehicles will be equipped with many local controllers for various functions, rather than a central unit.

Distributed controller

For example, a door controller is responsible for putting Windows, speakers, lights, mirrors, and other components into the electrical input before it can work. In this case, the wires are short and can be fully contained within the door assembly.

The doors will then be connected to the vehicle's data bus with just two wires, which also provide power to the electrical components. All the complex functions of a door can be achieved with just two wires, compared to more than a dozen in a conventional car, which is what Tesla has done with the Cybertruck.

The electric pickup uses a steer-by-wire system that requires a high-speed (low-latency) communication bus to transmit steering wheel motion in real time to the wheels of the Cybertruck. This is why the CAN bus used by most cars today is deficient: it has low data throughput (about 1 Mbps) and high latency. Instead, Tesla used a gigabit Ethernet architecture version with Power over Ethernet capabilities, using the same data cables to power the components.

The data network Tesla uses in the Cybertruck has a latency of just half a millisecond, perfect for turn signals. It also provides enough bandwidth to allow the various controllers to communicate in real time, working as a unit. Tesla was granted a patent for the communication system in December, and Cybertruck takes full advantage of it. However, Tesla has another advantage that could help simplify manufacturing. That's crucial for Tesla's $25,000 electric car, which it plans to launch in 2025.

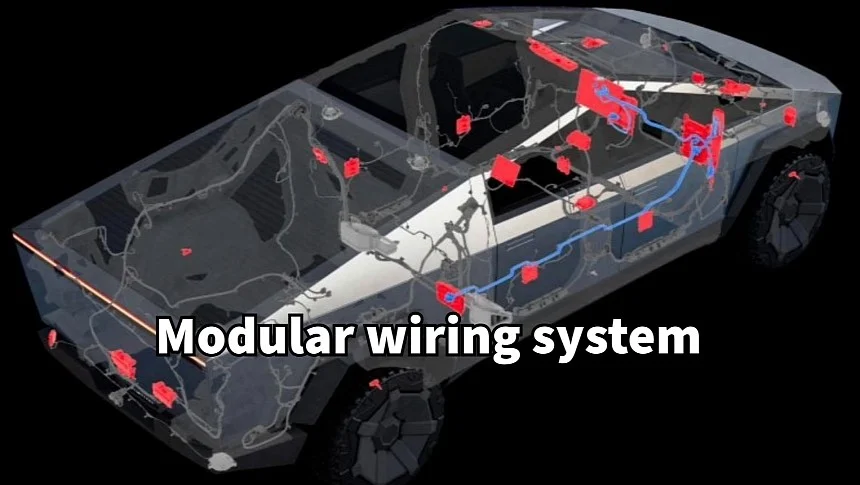

Modular wiring system

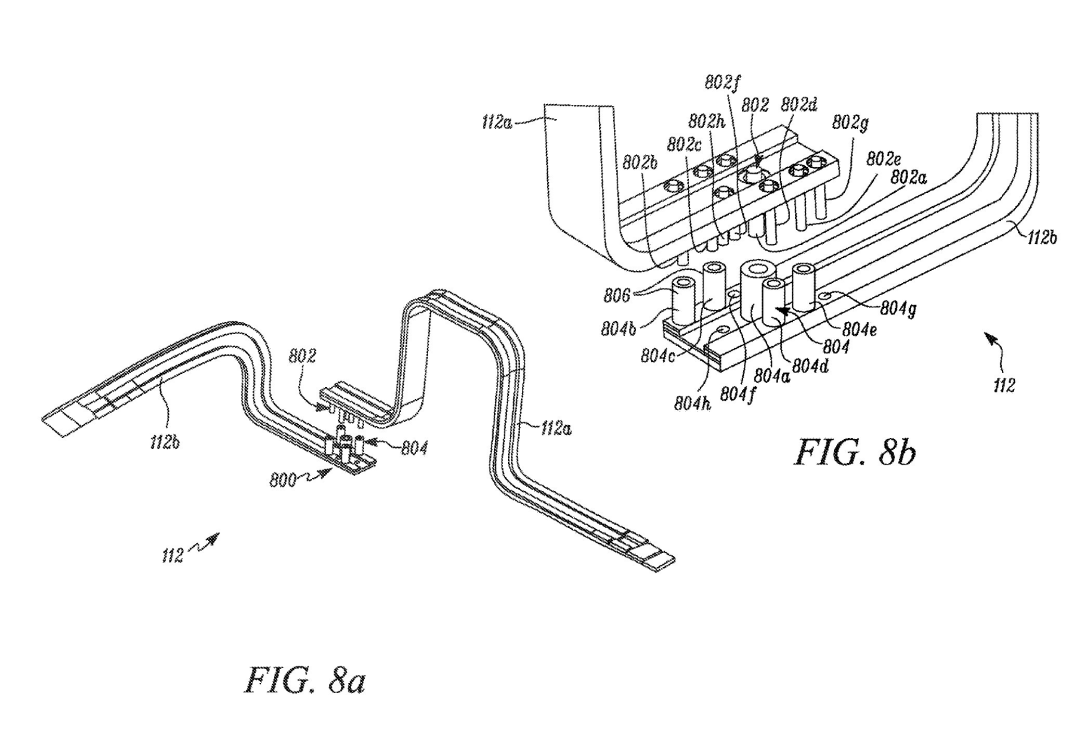

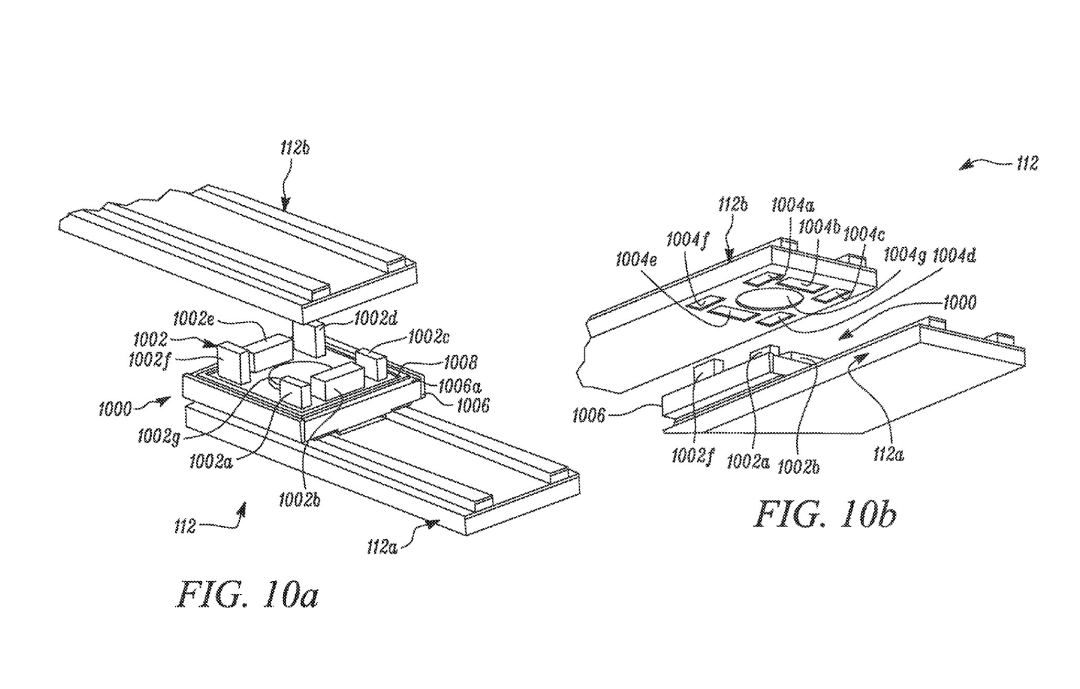

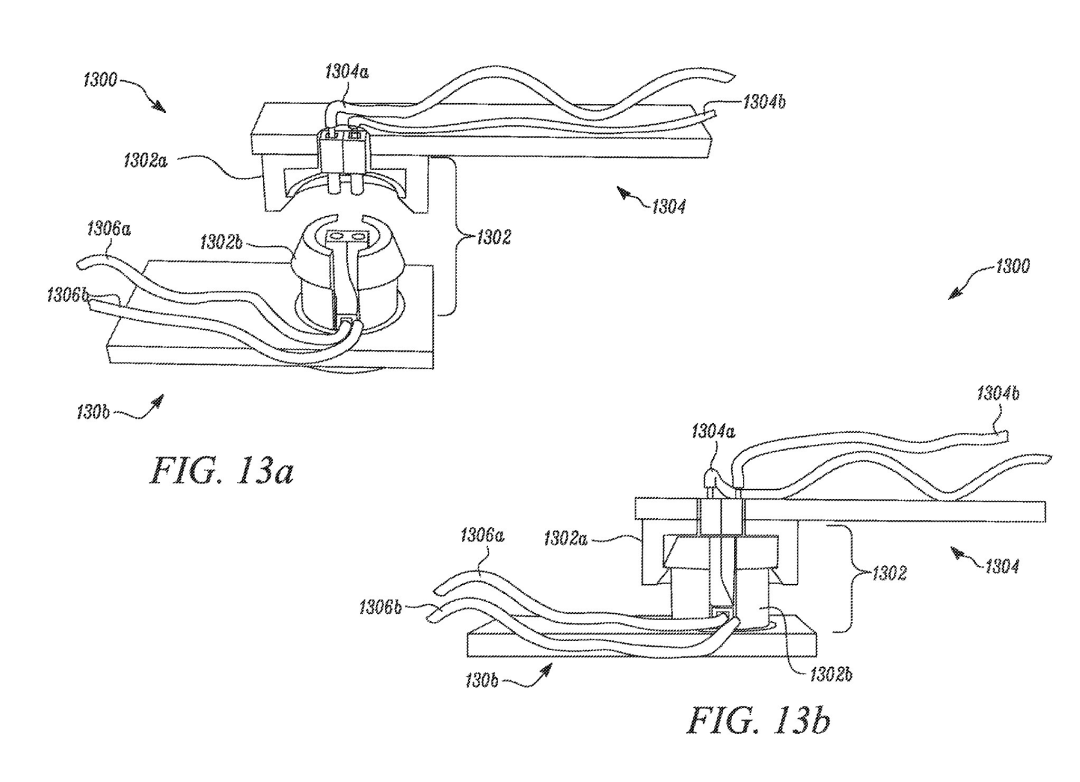

According to a recent patent application titled "Cabling System Architecture," Tesla has designed a modular cabling system that could greatly simplify manufacturing. This includes backbone wiring for power and data and is shielded by EMI to limit interference. The best part is that this modular wiring includes conductive paint and adhesives on the body, which supports robotic assembly and Tesla's new unboxed vehicle manufacturing process.

|

|

|

|

Wiring patent

According to the graphics included in the patent application, the modular cabling system would make the cables obsolete, and the components would snap into place thanks to proprietary connectors. It's also flat, so the wires don't stick out or even stand out. Unlike wire harnesses that need to be manually installed by workers on the production line, the installation of modular wiring systems is more suitable for automation.

Instead, connectors for flat wiring systems are included in every car part, from structural panels to more complex components such as car doors. Installing these components also involves establishing the necessary connections, similar to how Lego bricks are glued together. This reduces production time and costs.

I'm not sure if Cybertruck includes this type of wiring, though it certainly uses an automotive-grade gigabit Ethernet bus instead of a CAN bus. However, the two systems work seamlessly together and can have dual benefits when used together.

Tesla's planned low-cost model may not use steering-by-wire or other fancy components, but it certainly requires a fast communications backbone and a modular cabling system, as described in the patent below.

Dongguan Aichie Tech Electronics Co., Ltd. was founded in 2014, focusing on connectors, all kinds of wiring harnesses, wire and cable assembly and other electronic products technology development, we have strong technical expertise, research, development, design, manufacturing and sales combined and develop a good marketing system, with advanced manufacturing equipment and product testing capabilities, after years of operation and development, Wiring harness, connector, wire and cable product sales have been spread all over the world.

If you need electronic cable assembly, please contact us (sales03@aichie.com) for competitive prices and one-stop wire harness cable assembly solutions.