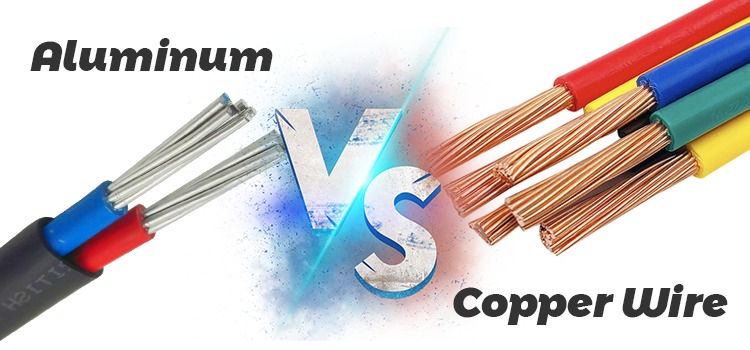

In the wiring harness industry, will aluminum wire replace copper wire in the future?

With the popularity of new energy vehicles, there is no doubt that automotive wiring harness materials have brought new challenges and opportunities. Whether aluminum wire will replace copper wire harness is not a simple question, but a complex issue involving material science, cost control, performance requirements and other factors.

From a performance point of view, copper wire is indeed superior to aluminum wire in terms of electrical and thermal conductivity. Copper has a higher conductivity than aluminum, which means that when transmitting the same current, copper wires generate less resistance and heat, which improves energy efficiency. In addition, copper is mechanically stronger than aluminum, which helps ensure the stability and safety of the harness in the complex and changeable automotive environment.

However, aluminum wire is not without its advantages. First of all, the density of aluminum is small and the price is relatively low, which makes aluminum wire have a significant advantage in cost. For new energy vehicles that pursue cost control, the use of aluminum wire can effectively reduce manufacturing costs. Secondly, the light weight of the aluminum wire helps to achieve the lightweight of the car, thereby improving the driving range and reducing energy consumption.

One: Advantages of copper wire

1, low resistivity: the resistivity of aluminum cable is about 1.68 times higher than that of copper cable.

2, good ductility: the elongation rate of copper alloy is 20~40%, the elongation rate of electrical copper is more than 30%, and the aluminum alloy is only 18%.

3, high strength: the allowable stress at room temperature, copper is 7~28% higher than aluminum. Especially the stress at high temperature, the difference between the two is very far.

4, bending resistance: aluminum repeated bending is easy to break, copper is not easy. In terms of elasticity index, copper is also about 1.7 to 1.8 times higher than aluminum.

5, large current load: due to low resistivity, the copper cable of the same section is about 30%-50% higher than the current load allowed by the aluminum cable (the maximum current that can be passed), especially the more and more household appliances, and the basic copper wire for home improvement.

6, low voltage loss: due to the low resistivity of the copper cable, in the same section through the same current. The voltage drop of copper cables is small. Therefore, the same transmission distance can ensure higher voltage quality; In other words, under the allowed voltage drop conditions, the copper cable transmission can reach a long distance, that is, the power supply coverage area is large, which is conducive to network planning and reduce the number of power supply points.

7, low heat: under the same current, the heat of the copper cable with the same section is much smaller than that of the aluminum cable, making the operation safer.

8, low electrical loss: due to the low resistivity of copper, compared with aluminum cables, copper cables have low power loss, which is obvious. This is conducive to improving the efficiency of power generation and protecting the environment.

9, good stability: the connection head of the copper cable is stable, and there will be no accidents due to oxidation. The unstable joints of aluminum cables often cause accidents due to the increase of contact resistance and heating due to oxidation. Therefore, the accident rate is much greater than that of copper cable. Especially in some places where copper and aluminum wires are connected, there is a problem after a long time. So copper wire and aluminum wire docking must be strictly required to be connected.

10, convenient construction:

① The copper wire is flexible and the allowed bending radius is small, so it is convenient to turn and easy to Pierce the pipe;

② Repeated bending of copper wire is not easy to break, so the wiring is convenient;

The mechanical strength of the copper wire is high, and it can withstand a large mechanical tension, which brings great convenience to the construction and laying, and also creates conditions for the mechanized construction.

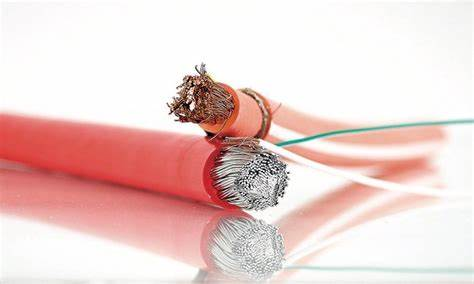

Two: copper wire shortcomings

1, easy oxidation: the air is easy to be oxidized, so the copper wire will form a layer of oxide on the surface after a long time of use, which will affect the conductivity of the copper wire.

2, vulnerable to corrosion: Copper wire is vulnerable to corrosion in a humid environment, which will lead to a decrease in the electrical conductivity of copper wire. Corrosion can also cause cracks and fractures on the copper wire surface, which can affect the life of the equipment.

3. Ratio: the proportion of copper wire is larger than that of aluminum wire, which does not have an advantage in the use of overhead high-voltage wire; Overhead lines often use aluminum wire, ground wire is usually used copper wire

4. High price: Compared with aluminum wire, the price of copper wire is more expensive than aluminum wire

Three, aluminum wire advantages

1, the price is cheap: copper rod is 3.5 times the price of aluminum rod, the proportion of copper is 3.3 times that of aluminum, so aluminum cable is much cheaper than copper cable, suitable for low-capital projects or temporary electricity.

2, the cable is very light: the weight of the aluminum cable is 40% of the copper cable, and the construction and transportation cost is low.

3, anti-oxidation and corrosion resistance: aluminum reacts with oxygen in the air to quickly generate an oxide film, which can prevent further oxidation, so aluminum wire is a high voltage, large cross-section, large span overhead transmission must be selected materials, but these advantages are no longer used as low-voltage lines.

Four, aluminum wire shortcomings

1, low strength: compared with copper wire, the strength of aluminum wire is much lower, which means that in the process of use, aluminum wire is more likely to break, break and so on.

2, susceptible to external force: the softness of aluminum wire is good, but this also makes it vulnerable to external forces, such as extrusion, stretching, bending, etc., these external forces may lead to aluminum wire more deformation, damage and other problems.

In practical applications, many new energy vehicles have begun to try to use aluminum wire bundles. For example, Xiaomi's new energy vehicle brand uses aluminum high-voltage wiring harnesses in its latest models to reduce costs and increase driving range. This attempt has received positive feedback from the market, proving the feasibility of aluminum wire bundles in new energy vehicles.

However, the popularity of aluminum wire bundles has not been smooth sailing. The chemical properties of aluminum are more active, and it is easy to react with oxygen in the air, resulting in increased resistance and unstable current transmission. This problem is particularly prominent in the complex and changeable working environment of automobiles. Therefore, in order to ensure the stability and safety of the aluminum wire bundle, special anti-corrosion measures and appropriate connection technology are required. This undoubtedly increases the research and development and manufacturing costs of aluminum wire bundles, and also limits their wide application to a certain extent.

In addition, although the aluminum wire harness has advantages in terms of cost and lightweight, its performance shortcomings in terms of mechanical strength and corrosion resistance cannot be ignored. In some special circumstances, such as high temperature, high humidity and other harsh environments, the performance of aluminum wire bundles may be affected, and even cause safety hazards.

In summary, the implementation of new energy vehicles does not mean that aluminum wire will completely replace copper wire harnesses. In the foreseeable future, copper and aluminum wires will coexist and complement each other in the field of new energy vehicle wiring harnesses. Depending on different models and performance needs, car companies may choose to use copper wire or aluminum wire harness, or use a copper-aluminum hybrid wire harness design scheme.

As the old saying goes: "Every ruler has his weaknesses, and every inch has his strengths." Copper wire and aluminum wire have their own advantages and disadvantages, only according to the actual demand for reasonable selection and collocation, in order to give full play to their performance advantages, to contribute to the development of new energy vehicles.

In the future development, with the continuous progress of material science and technology, we look forward to seeing the application of more new materials in the field of wiring harnesses, bringing more possibilities to the development of new energy vehicles.

Aichie Tech Electronics Co.,Ltd provides customized wiring harnesses to all over the world, one-stop solutions, according to customer needs to use different wires and connectors, to provide customers with automotive wiring harnesses, new energy wiring harnesses, industrial wiring harnesses, electronic wiring harnesses and so on.

If you have any needs or knowledge of wire harness, wire and cables, please contact us: sales03@aichie.com.