Overview

The continuous rise of international crude oil prices, the whole society's greater concern about environmental deterioration and global warming, coupled with the tilt of governments' taxes and policy support, have prompted the market share of alternative energy, especially electric vehicles, to grow worldwide.

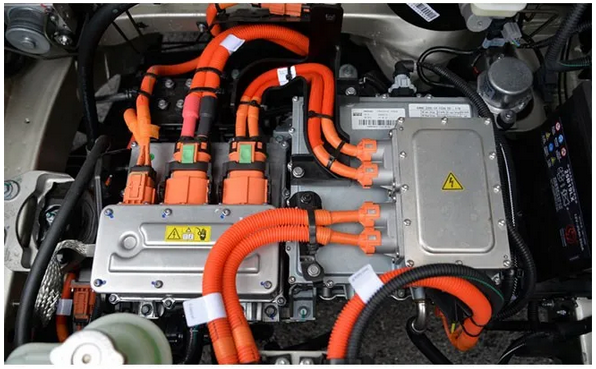

Electric vehicles mainly include three categories, namely pure electric vehicles, hybrid vehicles and fuel cell vehicles. Pure electric vehicles and fuel cell vehicles are driven entirely by an electric motor, while hybrid vehicles combine an internal combustion engine with an electric motor, supported by an electric motor when the internal combustion engine is less efficient at acceleration and low speeds. Their common feature is the use of up to 600V or higher drive voltages, when it comes to wiring, they all share the same basic requirements, both in the safe transmission of high currents and voltages under EMI (electromagnetic interference) protection systems. As a high-voltage cable, it is used to connect high-voltage batteries, inverters, air conditioning compressors, three-phase generators and motors to achieve the transmission of power energy.

The basic principle of electric cars seems simple. But in-depth analysis, system manufacturers are facing a series of challenges to overcome. New technical requirements are put forward for electric vehicle high voltage cables, their flexibility, shielding, safety, size and other items, because these will affect the wiring of high current and high voltage components. In the face of the different technical points of each possible power system, different special requirements are also put forward for the required components.

It should be noted that the high-voltage system of electric vehicles is not a typical high-voltage system, and relevant terms such as "high voltage" and "high current" must be limited to the scope of the automotive field, and the conventional low-voltage system of automobiles. Reference systems in other fields use completely different standards, such as the definition of high voltage in the power field starting at several thousand volts.

The requirements for high-voltage cables for electric vehicles

Innovative electric vehicle designs present new challenges for high-voltage cables and system components that cannot be fully adapted to existing solutions. The specific requirements are analyzed as follows.

1. Voltage

The basic difference with conventional automotive cables is that the structure needs to be designed at a rated voltage of 600V, while if used on commercial vehicles and buses, the rated voltage can be as high as 1000 V. By comparison, even higher. The cables currently used in cars powered by internal combustion engines are designed with a rated voltage of 60V.

With the power generated by the system (P= U×I) unchanged, the high voltage can reduce the power loss in the transmission system due to the use of lower current (PLOSS= I2×R).

2. Current

Since the cables connect batteries, inverters, and motors, high-voltage cables need to transmit high currents. Depending on the power requirements of the system components, the current can reach 250A to 450A. Such a high current is hard to find in a conventionally driven vehicle.

3. Temperature

The result of high current transmission is high power consumption and heating of the components. High voltage cables are therefore designed to withstand higher temperatures. At present, it can be seen that there is a further increase in temperature requirements.

In contrast, current vehicles usually use cables with a rated temperature of 105 ° C is sufficient, as long as the cable is not used in the engine compartment or other areas resistant to higher temperatures. High voltage cables for electric vehicles are usually higher than this temperature, such as 125 ° C or 150 ° C.

If the route through the electric vehicle is unfavorable, the Oems will even put forward higher requirements for high temperature resistance. Such as near the exhaust pipe, the front of the motor, the back of the battery, etc.

4. Working life

The design life of the cable in the automotive industry is usually 3000h in the specified temperature class. In recognized cable standards (such as ISO 6722, ISO 14572), this value is usually used for long-term aging tests. The special requirements of customers in the field of high pressure applications may exceed 3000 h, and the cumulative operating time at specified temperatures may even reach 12000 h.

5. Shielding Effect

The high-voltage cable itself does not need shielding, because it does not transmit data as coaxial cables do, but it is necessary to prevent or reduce the high-frequency radiation generated by the switching power supply in the system through the cable to induce peripheral components.

Unlike fuel-powered vehicles, the three-phase alternating current that controls the electric motor in an electric vehicle is required. Sinusoidal voltages carrying energy are equivalent to square-wave pulse signals of different frequencies. Because the high frequency pulse has a steep edge, it will produce a very energetic harmonic emission to the surrounding area.

EMI problems can be solved by using proper shielding methods. In some cases, to meet the different requirements of the shielding effect, it is necessary to use a combination of different shielding types.

6. Flexibility

The challenge in the development of hybrid vehicles in many cases is that the existing series platform was originally designed only to carry the gasoline engine and its components into the space incorporating more electrical components. Even without considering wiring, space limitations can be expected. In addition, cables and connectors require space to be routed through. The usual consequence is a strained bending radius.

Due to the inherent design of conventional cables, high bending forces are difficult to overcome. In order to solve this problem, high flexibility of high voltage cables is essential. Only a more flexible design can be easily implemented through vehicle routing.

7. Resistance to bending

If the motor is located near the moving part of the vehicle and then causes the connected high-voltage cable to vibrate continuously, it needs to be designed to withstand high cyclic bending to ensure good bending endurance.

8. Identification

Because of the increased application risk caused by high voltage, various standards define that high-voltage cables must be visually distinguishable from ordinary automotive cables, and the specified surface must be bright orange.

It can also print warnings and special signs, such as "Caution! High voltage 600V ", high voltage lightning mark, etc.

The standardization of electric vehicle cables

In view of the above challenges and requirements of high voltage cables for electric vehicle applications, it is necessary to establish new cable standards to meet the needs of suppliers, wiring harness factories and Oems.

This work is being carried out by the Working Group on Automotive Cables of the Electrical and Electronics Sub-Technical Committee of the ISO Road Vehicle Technical Committee (ISO/TC 22 / SC 3 / WG4).

As can be seen in ISO 6722, based on the common 60V cable standard, it has been revised to meet the needs of 600V cables. Because most of its requirements are still very general, but often do not consider the special design required for high-voltage cables. A similar revision was made to ISO 14572.

The standardization of high voltage cables with voltages above 600V is a topic of the automotive wire working Group. The standard is ISO 17195. It was later merged into the new standard project ISO19642 as several parts of the ISO19642-X series of standards.

SAE adjusts the current high voltage (rated 600V) specification SAEJ1654 to the requirements for high voltage cables and covers voltage ratings from 600 to 1000 V, the newly created and published standard SAE J2840 defines the type of cables for shielding.

LV is the common procurement specification of the five major German automobile companies, and currently launched the LV 216 high voltage cable standard for electric vehicles with a rated voltage of 600 V. It covers single and multi-core shielded cables.

China's national automotive industry standard for high-voltage shielded cables has been issued and implemented, and its rated voltage will reach DC1500V/ AC1000V, and the standard number is QC/T1037-2016.

Electric vehicle high-voltage cable structure design

Standard products and very specific requirements are difficult to define. The purpose of this paper is to address the basic design ideas and overcome the challenges described above by applying advanced high-voltage cable construction principles.

1. Conductor design

The flexibility of high-voltage cables is mostly determined by the design of conductors. This is why high-voltage cables use special conductors with a large number of very small diameter monofilaments. A certain number of monofilaments are first twisted, and then concentric retwisted to form the soft conductor needed for high voltage cables.

Another benefit of having more roots is better resistance to bending. The stranding pitch is shortened, and the bending life of the high voltage cable can be increased.

2. Insulation Materials

The selection of insulating materials is mainly to consider heat resistance requirements and mechanical strength. Compared with standard battery cables, softer materials can be reasonably selected to keep the specially designed stranded conductors flexible.

3. cable

Cables with multiple cores usually need to be twisted together. In order to make up for the deformation caused by stranded high-voltage cable cores, special equipment called untwisting is needed. In this process, the pay-off disc equipped with the special strander rotates in the opposite direction of the stranding. This is necessary to prevent deformation tension in the cable.

Depending on the structure of the cable, padding is usually used to ensure a higher concentricity of the shielded cable and ultimately achieve a satisfactory high-voltage cable. The use of tape in the twisted cable core can maintain the flexibility of the cable.

4. Shielding

Due to the requirements of EMC (electromagnetic compatibility), the braided shield is composed of multiple copper wires. Tinned copper wire can make it more resistant to environmental effects such as oxidation. Using thin copper wire can maintain the design flexibility of the shield required to have a coverage of more than 90% to overcome the EMI problems described earlier

For different needs of shielding effect, braided shielding can be combined with various other shielding, such as aluminum-plastic film. screen

The cover can be wrapped with a layer of non-woven fabric to ensure that the jacket is easily removed during assembly.

5. Sheath

As with the insulation of the core, the sheathing material is selected according to thermal and mechanical requirements. Due to direct contact, environmental properties such as liquid resistance and wear resistance are also particularly important for the sheath. These characteristics mainly depend on the type of sheath material selected, and to some extent are also affected by the design of the sheath structure.

If special requirements, such as overcoming the wear of the installation vehicle environment, require increased wear resistance, this needs to be considered when selecting materials. Test equipment is often used to simulate real-world situations to verify these characteristics.

Choose softer materials to benefit from flexibility, which may lead to lower wear resistance of high-voltage cables. According to the relevant regulations, the extrusion jacket should be a bright orange, according to the regulations can also add a special warning high-pressure mark. ,

Characteristics and optimization of high-voltage cables for electric vehicles

The perfect complex design and the use of high-quality materials will result in expensive cable costs. Experience has shown that for specific high-voltage cables, they can often be tailored through the optimization of cross section, temperature requirements, flexibility and shielding effect. Weight and cost savings can be demonstrated, excessive size and excessive components can be avoided.

1. Optimization of cross-sectional area and temperature class

The choice of cable is mostly based on the ambient temperature and transmission current indicators. In this regard, the most important characteristics are "cable cross section" and "heat resistance grade of the material used in the cable".

The voltage drop of the conductor is converted into thermal energy to heat the conductor of a high-voltage cable. This heat can be partially transferred to the environment to reduce the operating temperature of the wire. A lower temperature gradient can transfer less heat. Continuous load current cable can

To lead to the highest rated temperature. This temperature can cause the aging of the materials used.

Cable designers face the challenge of designing the most appropriate cable for the application: Excessive conductor specifications can lead to increased cost and weight, and larger outer diameters. The worst case scenario, considering only the highest possible load current and ambient temperature, will lead to the adoption of large section cables, high temperature resistant materials such as organofluorine or silicon materials.

Determining the relationship between the current and the ambient temperature of the load is very meaningful from a technical and economic point of view. Real driver periodic dynamic current peaks should be considered, allowing reasonable definition of worst-case load current and peak current.

A prerequisite for a good design is an understanding of the basic conditions, such as the ambient temperature and cable load must first be determined. Generally, large-section high-voltage cables have large inertia in terms of temperature change, so the current peak of vehicle acceleration or deceleration will not cause a large conductor temperature effect. Sometimes short-term temperature peaks are allowed even if exceeded above

The ability of a high-voltage cable to handle these spikes is usually defined by thermal overload performance. Thus, the cable does not need to be designed for a higher operating temperature class, and it is not necessary to use a cable that exceeds the specified operating temperature. The resident load current as well as single or serial pulses can be considered together with various parameters such as ambient temperature.

The combination of theoretical basis and practical experience can initially identify, select and optimize the high-voltage cable that meets the application.

Figure 1. Current carrying capacity and temperature rise of XLPO cable in AC state of 150 ° C heat resistance

2. Flexibility optimization

The available space for vehicle cabling deserves careful consideration. The need for a tight bend radius in only one specific area of the vehicle results in increased flexibility requirements for the overall cable. If it is possible to make small changes in the overall design, it makes sense to avoid tight bending problems.

It is not necessary for the cable to have the highest flexibility. The exact definition of the bending force, combined with the construction and corresponding test equipment, allows the cable designer to create the most suitable design for the application. Especially for cables with larger sections, replacing highly flexible designs with more flexible or conventional structural designs can significantly reduce costs.

3. Optimization of shielding effect

The shielding effect defined in a certain frequency range is very necessary for the development of the cable. The masking effect without information about the frequency is not very useful, which can lead to solutions with excessive size and the use of expensive combination masking, which is no longer necessary from a technical point of view.

Under normal circumstances, the electric vehicle cable development and design stage can be used to give an expected effect value for consideration. Then the shielding effect of the high-voltage cable is verified by the actual test means.

Remarks

The high-voltage wiring harnesses of electric vehicles and traditional wiring systems still have a long way to go. Specific specification requirements are often not clearly defined, which can cause technical complications and lead to expensive solutions.

All parties involved in the development phase must adopt a systems-oriented approach to the rational optimization of high voltage cable technology and costs. These parties may include cable, connector, and component suppliers, wiring harness factories, and Oems. The knowledge accumulation of the whole system and the specification of a high voltage cable oriented to the target requirements are the basis of optimal design. The research and development department of cable manufacturing uses theoretical calculations as well as suitable measurement equipment to demonstrate the ability to develop cables that are more suitable for the application.