HV Cable selection

1. Cable diameter

According to the layout diagram of each high-voltage electrical component of the vehicle, the main circuit and branch circuit are distinguished, and the responsible characteristics of the high-voltage components connected to the high-voltage wiring harness are determined. Characteristics include working voltage, rated power, peak power, rated current, peak current, duration, etc.

The operating temperature and ambient temperature also have an impact on the cable diameter. Since high current transmission will lead to high power consumption and increased temperature rise of related components, the design of high voltage cables must be able to withstand higher temperatures. If the cable layout environment exceeds the allowable operating temperature of the cable, a cable with a larger cross-sectional area must be selected. When Tmax reaches 180°C, the cross-sectional area of the conductor needs to be raised to one gear, and when Tmax reaches 250°C, the cross-sectional area of the conductor needs to be raised to the second gear. the

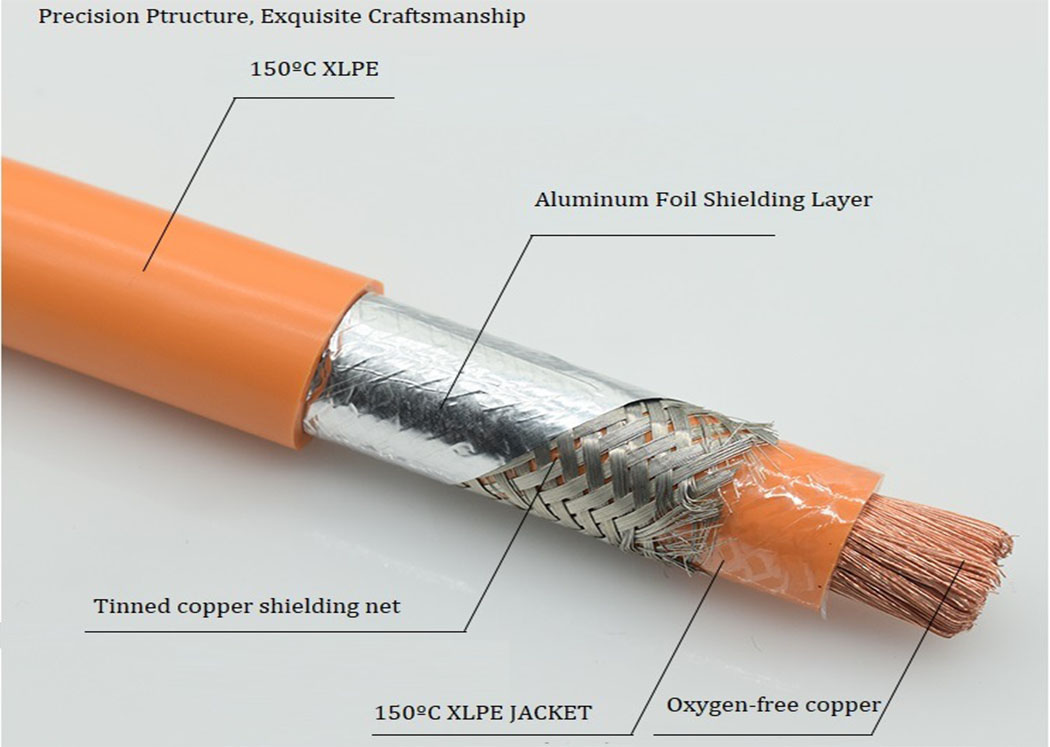

2. Cable structure

High-voltage cables are divided into single-core cables and multi-core cables in terms of types. The cross-section of high-voltage cables is round and the color of the sheath is orange. The multi-core cable is composed of multiple single-core wires. The single-core wire must meet the relevant technical parameters of the single-core cable at the same time. If the multi-core cable is used for signal transmission, please use separate shielding to ensure that the signal is not lost. The wires are mainly made of multi-core annealed copper stranded wires to meet the technical requirements of the internal resistance and flexibility of the wires. The insulation layer must be resistant to high and low temperature and flame retardant, and most of them are composite structures. For EMC protection, high-voltage cables with shielding layers are braided on the inner sheath layer with bare copper or copper-plated wires, and the braiding density is ≥90%.

High voltage connector selection

1. High voltage connectors

In terms of electrical performance: it is necessary to consider related electrical performance parameters such as rated operating voltage, rated operating current, insulation resistance, withstand voltage level, shielding and interlocking. the

Environmental performance: It is necessary to consider the requirements of working temperature, ambient temperature, salt spray level, flame retardant level, resistance to solution reagents, and prohibited substances. According to different design requirements, there will be other requirements. In terms of mechanical properties: test the vibration resistance and the corresponding mechanical life according to different working conditions.

In terms of safety performance: high-voltage interlock is adopted, which is divided into built-in type and external type. Because the built-in type has a compact layout and small size, electric vehicles all use built-in type, and the high-voltage interlock is detected by controllers such as VMS or BMS. Requirements After the high-voltage connector is separated, the live part can be reduced to below 60Vd.c and 30Va.c within 1S. To ensure personal safety.

2. Service switch

MSD, the manual maintenance switch, is a key component to ensure the high-voltage electrical safety of pure electric vehicles. It is an executive component that can realize the electrical isolation of the high-voltage system at critical moments. It can highly integrate the breaking device and the fuse, and configure a suitable fuse inside. At the same time, it can also protect the circuit from overcurrent and short circuit protection. Reasonable design, operation and maintenance of the switch play a vital role in the electrical safety of electric vehicles. the

3. Charging interface

The charging interface is currently divided into two types, the AC charging interface and the DC charging interface, and the AC interface is to connect the AC grid power to the vehicle charger through the cable control and protection device. The DC interface is to directly connect the DC power supply equipment with control and guidance function to the electric vehicle battery. The rated voltage of the AC interface is 250Va.c or 440Va.c, the rated current does not exceed 63A, the rated voltage of the DC interface is 750Vd.c or 1000Vd.c, and the rated current does not exceed 250A. The rated voltage and current of the charging interface is determined according to the layout requirements of the vehicle Value, other relevant electrical characteristics of the AC and DC charging interface and other parameters must meet the requirements of the national standard GBT20234.2-2015 and GBT20234.3-2015.

Aichie provides high voltage ev cable assembly, high -quality busbar and low -voltage auto wiring harness around the world. It has introduced new production equipment, which greatly improves the quality and efficiency of production. Customers are widely distributed in Europe and North America. Production employees and experienced engineering teams and sales teams serve our customers; please contact us now! We will provide you with competitive prices!

AICHIE Tech Electronics Co.,Ltd

Email: sales03@aichie.com

Mobile/Whatsapp/WeChat: (86)18027502150

Skype: live:.cid.8643b3df38ff8b5